Computational clues into the structure of a promising energy conversion catalyst

Hydrogen fuel is a promising source of clean energy that can be produced by splitting water into hydrogen and oxygen gas. The reaction is difficult but achievable with the help of a catalyst, a material that can speed up the process. However, current catalysts lack the efficiency required for water splitting to be commercially competitive. Recently scientists have identified one such catalyst, iron-doped nickel oxide, as a highly active compound that can speed up this reaction, but the origin of its activity is not well understood.

Now researchers at Princeton University have reported new insights into the structure of an active component of the nickel oxide catalyst, known as β-NiOOH, using theoretical calculations. Led by Annabella Selloni, professor of chemistry at Princeton, the findings were published in The Journal of Physical Chemistry Letters on October 28.

“Understanding the structure is the basis for any further study of the material’s properties. If you don’t know the material’s structure you can’t know what it’s doing,” Selloni said. Nickel oxide’s exact structure has been difficult to determine experimentally because it is constantly changing during the reaction.

The research team took a theoretical approach and employed a “genetic algorithm” to search for the structure. Genetic algorithms operate under a set of parameters that draw inspiration from evolution by creating generation after generation of structures to arrive at the most “fit” or most likely candidates.

Taking the results of the genetic algorithm search in combination with computational techniques known as hybrid density functional theory calculations—which estimate a molecule’s electronic structure—Li and Selloni were able to identify structures of nickel oxide that supported existing observations.

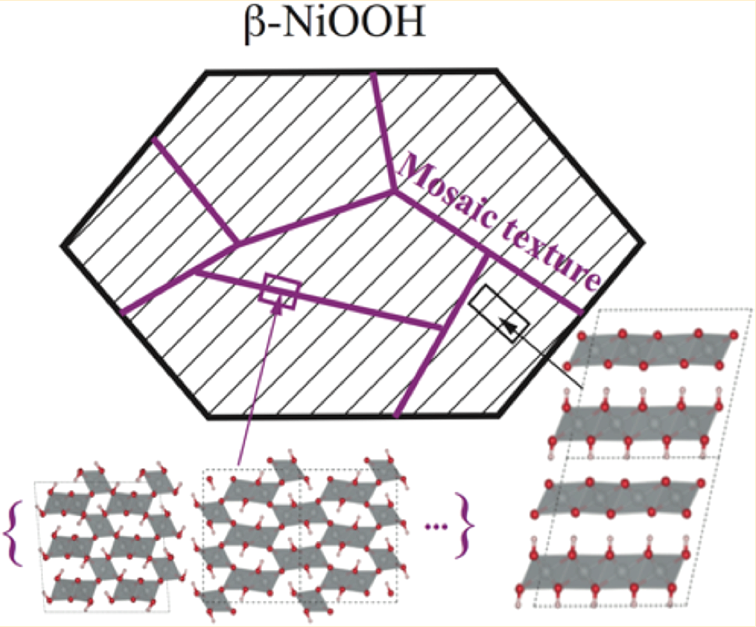

One such observation is the material’s mosaic texture, composed of tiny grain-like microstructures. The researchers propose that these microstructures are stable tunnel structures that relieve stress between layers. Another observed feature is the doubling of the distance between layers made of the same material, referred to as its c axis periodicity, which represents the alternating layers of Ni(OH)2 and NiO2 formed during the reaction.

Armed with a better understanding of the material’s structure, the scientists hope to further map out its activity in the reaction. “I’m interested in the microscopic mechanisms, what are the electrons and atoms doing?” Selloni said.

Read the full article here:

Li, Y.-F.; Selloni, A. “Mosaic Texture and Double c-Axis Periodicity of β–NiOOH: Insights from First-Principles and Genetic Algorithm Calculations.” J. Phys. Chem. Lett. 2014, 5, 3981.

This work was supported by the US Department of Energy, Division of Chemical Sciences, Geosciences and Biosciences under award DE-FG0212ER16286.