How do you densely pack a bunch of spheres? Ask an algorithm

Four hundred years ago, no less a sailor than Sir Walter Raleigh set mathematicians the challenge of packing cannonballs onto the deck of a ship for maximum quantity. The astronomer Johannes Kepler offered a solution, later known as Kepler’s Conjecture – a mathematical equation we see today in supermarkets that stack oranges into pyramids.

The timeworn challenge of packing spheres, evolved to meet modern technology, has found new expression in a California-based additive manufacturing startup founded by a Department of Chemistry alumnus and spurred by a robust packing algorithm developed years ago in the Torquato Lab.

Hopkins image courtesy of Uniformity Labs; Torquato image by C. Todd Reichart.

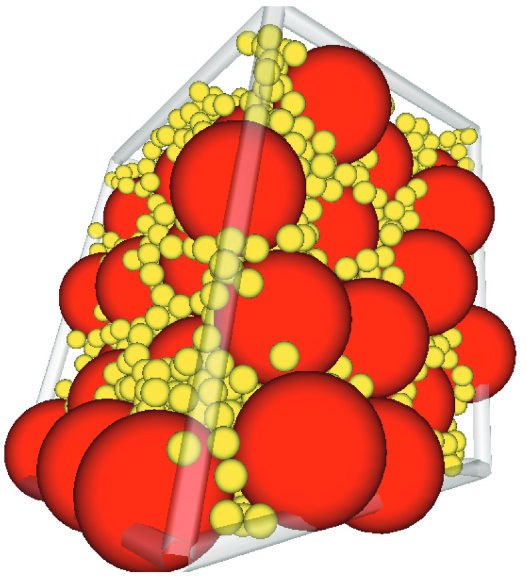

Using that algorithm to optimize ratios of different-sized spheres, Uniformity Labs, Inc. produces novel metal and composite powders for 3D printing that exhibit an unprecedented density – meaning, a huge reduction in the space between particles – where the number of particle contacts is estimated to be 100 to 100,000 times greater than that produced by previous processes.

The powders also allow for uniformity in how particles are distributed, and improved flow spreadability. In the most prominent form of metal 3D printing, thin layers of powder are spread onto a surface and the particles are fused with a fast-moving laser. The more uniform the spreading, the better the fusion.

No one to-date has united these advantageous properties so successfully in one material. Together, Uniformity Labs and the algorithm – colloquially called “TJ” for Torquato-Jiao after its creators – just may revolutionize industrial 3D printing.

“I believe we’re in a materials revolution,” said Adam Hopkins, the CEO of Uniformity who earned his bachelor’s degree in physics at Princeton in ’05 and his doctorate in chemistry in ‘12. “The new computational capabilities are leading us to be able to theoretically identify materials that we wouldn’t otherwise know are out there. This technology is a case in point.”

Investment firms apparently think so, too. Last month, Uniformity completed a $38.35M financing round that paired initial investors with new financial and strategic partners. With a strong balance sheet, the company, based in Fremont, California, has begun a capacity expansion and new round of hiring.

“Princeton researchers are dedicated to making discoveries that often can provide new solutions for technological challenges,” said John Ritter, director, Office of Technology Licensing at Princeton University. “Companies such as Uniformity Labs serve as an important conduit to transform academic research findings into real-world solutions. It is exciting to see the strides that Uniformity Labs has made in translating this research into innovations for the manufacturing industry.”

Image courtesy of the Torquato Lab.

For his own part, Salvatore Torquato, the Lewis Bernard Professor of Natural Sciences, professor of chemistry, associated professor in the Department of Physics, and one-half of the team that created the TJ algorithm, finds his involvement with a start-up somewhat startling.

“This is a little weird for me, because my work tends to be really abstract and theoretical. But I’ve been interested in the ancient problem of densely packing solid objects for my entire academic career,” said Torquato.

“Years ago, I suggested that Adam apply the Torquato-Jiao algorithm to the case of spheres with two different sizes,” he said. “The thinking was that the efficient TJ algorithm would outperform previous algorithms for spheres of different sizes to produce disordered packings of unusually high densities.

“Indeed, this was the case.”

A HANDFUL OF SUGAR

The TJ algorithm searches a vast, theoretical parameter space to identify what Torquato calls the “magic numbers.” They represent the best possible – and the best knowable, considering that the search space is infinite – ratios between the sizes of the particles and their compositions. This allows for both dense packing and uniform particle spreading in industrial application. Together, these properties can boost 3D printing speeds manyfold, and use energy more efficiently in the process.

No matter what the problem involves – particles in a powder or stacking cannonballs on a ship’s deck – the ultimate goal is to fill up the volume by squeezing out as much empty space as possible. Hopkins analogizes the challenge by calling to mind a handful of sugar.

“A handful of granulated sugar is about 50% particles and 50% space between them. That’s a lot of space,” said Hopkins. “The challenge is to mix different sizes of particles so that space is more efficiently filled, while maintaining a uniform spatial distribution of the different particle sizes and good rheological properties, flowability, and spreadabilty.”

The TJ algorithm used by Uniformity was originally presented in a 2010 paper in Physical Review authored by Torquato and Yang Jiao, a former Ph.D. student, about spheres of uniform size. In 2013, with Hopkins as co-author, a second paper was published in the same journal on binary spheres, or, spheres of two different sizes that are packed in a “disordered” arrangement.

“We found that in certain situations, random, or disordered, packings of a few different sizes of spheres can be almost as dense as the densest ordered packings made from those same spheres,” said Hopkins. “That was a theoretical discovery. We then brought it into practice and found the circumstances under which mixed powder stays mixed, keeping that uniform distribution of particles throughout various industrial handling, spreading, and processing steps.”

“We found that in certain situations, random, or disordered, packings of a few different sizes of spheres can be almost as dense as the densest ordered packings made from those same spheres,” said Hopkins. “That was a theoretical discovery. We then brought it into practice and found the circumstances under which mixed powder stays mixed, keeping that uniform distribution of particles throughout various industrial handling, spreading, and processing steps.”

This new capacity to produce disordered sphere packings with unusually high densities has significant practical implications, particularly where density is critical to material properties and fabrication cost. Examples are solid propellants, ceramics, and concrete.

In fact, Hopkins and Torquato originally sought to apply the TJ algorithm to the production of better concrete, with the packing ratios applying to the composite rocks, sand, and other aggregate. Though the application was successful, metal powders and 3D printing offered a more expedient path to commercialization.

Adam Hopkins is scheduled to speak at the Wednesday, April 21, 2021 Materials Science Symposium of the Princeton Institute for the Science and Technology of Materials (PRISM). Registration for this event opens soon.